Great question! First, let’s quickly talk about what is the difference between an area monitor and a personal monitor. An area monitor, like the name describes, is an instrument placed in a specific area to monitor the chemical concentration in that area. Typically, either the user or the manufacturer will set alarms at specific concentrations to alert when the chemical is detected at or above those concentrations. Personal monitoring, on the other hand, is when a monitor is worn by the employee to determine their actual exposure to the chemical. Knowing the exposure dose is extremely useful if an exposure occurs to determine what, if any, medical treatment might be needed.

Again, area monitoring is used to characterize the overall site air quality. The placement of the air monitors in areas suspected of producing higher concentrations may help to determine where air sampling (personal) might be necessary. A combination of area monitoring and personal monitoring in the same area over the same period of time allows the company to see trends in the accuracy of the data, correlate area monitoring results to personal monitoring results and improve area monitoring placement to best capture accidental releases.

Using a combination of air monitoring and air sampling paints the best “picture” of potential chemical exposure in the workplace. Now let’s consider a workplace that contains many sites within the company where chemicals are used. For simplicity in this exercise, let’s assume that the company only has one chemical and thus is using an area monitor and personal sampling methods specifically for targeting that chemical.

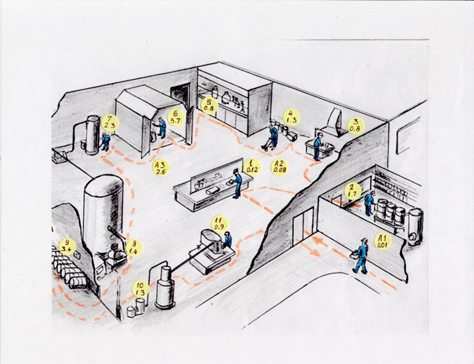

Using the drawing on the right, let’s assume that the area monitor is on the ceiling in the center of the room. Let’s also assume that the chemical is present in all of the numbered positions. As is shown in the drawing, Employee Blue is travelling throughout the facility to perform their job and in possible contact with each site where the chemical is present, but contained. Now let’s look closer at location 8. If Employee Blue is performing maintenance on the tank at location 8 and a small leak develops, Employee Blue would be exposed to the chemical first. Depending upon the volume of the room and the concentration and type of the chemical, the chemical may eventually reach the area monitor, but only after the employee’s initial exposure.

Now, let’s consider a scenario where Employee Blue is not restricting their movement to the large room but may also need to access Location 2. Location 2 is the storage area for the chemical. If Employee Blue enters Location 2 and is exposed to the chemical at a concentration below the chemicals’ odor threshold and continued to work in the environment, it is highly likely the employee could exceed the safe exposure limit without even knowing. However, if Employee Blue is wearing a personal air monitor, the monitor would detect the chemical and alert the employee. The area monitor in the other room would not detect the presence of the chemical because it was not in the area where the chemical release occurred.

In this scenario regarding Location 2, there is an assumption that the personal monitor was either an electronic or direct-reading colorimetric device to provide an immediate alert to the hazard. An area monitor provides important information regarding the overall air quality within a certain diameter of the device. However, chemical releases can occur anywhere chemicals are stored, transported or used and it is very costly to have area monitors in all potential areas. Personal monitors allow employees to know immediately if a chemical hazard is present and take action to prevent further exposure to themselves and others.

But let’s not forget that OSHA has the final say! According to OSHA regulation 29 CFR 1910.120, an air sampling strategy outlined in the site-specific health and safety plan must address frequency and type of air monitoring, personal monitoring and environmental sampling (29CFR1910.120 (b)(4)(ii)(E). This air sampling strategy is basically a tool that lays out how the company is going to perform the air sampling and where the chemicals are located within the company. A lot of the information about the chemicals is available in the safety data sheets (SDS) but the information about the location of the chemicals and the other process controls in place (e.g., ventilation) will need to be determined by the company. A certified safety professional (CSP) or a certified industrial hygienist (CIH) is a great asset to help develop the company’s air sampling strategy. For more information about those resources, visit the National Safety Council at www.nsc.org or the American Industrial Hygiene Association at www.aiha.org