WATER treatment

– Chemical Detection in the Water Treatment Industry

Detecting chemicals used to keep water clean

The processes used to treat and purify water involve both physical and chemical purification techniques. Many water treatment applications use toxic chemicals in their efforts to kill water-borne microbes and pathogens. Chlorine for example is widely used in water treatment plants because it can deactivate most microorganisms found in water at a relatively low cost. Additional chemicals that are present in water treatment applications include: ammonia, chlorine dioxide, hydrazine, hydrogen sulfide, and ozone. While these chemicals are effective for sanitization, they don’t only pose harm to the targeted microbes. Employees working, especially in enclosed spaces, with these water treatment chemicals are at a risk of exposure. SafeAir and ChromAir badges help to keep employees safe from chemical exposure when working in close proximity to toxic chemicals.

– Designed for the Water Treatment Industry

Chemicals Detected

AMMONIA

CHLORINE

CHLORINE DIOXIDE

HYDRAZINE

OZONE

– WATER TREATMENT –

NEWS & UPDATES

The Big Deal – Chemical Detection

What is Chemical detection and why do we need it? Believe it or not, the need for chemical detection is not just prevalent in chemical labs and big science corporations. In fact, the need spreads out over almost every industry in one way or another. From sanitizing...

If I have an area monitor, do I need to do personal monitoring?

Great question! First, let’s quickly talk about what is the difference between an area monitor and a personal monitor. An area monitor, like the name describes, is an instrument placed in a specific area to monitor the chemical concentration in that...

Exposure dose for dummies

To answer the question of how fast SafeAir badges will react, we will need to know the concentration of the chemical present in the environment as well as the overall time of the exposure. For example, the SafeAir TDI/MDI badge has an initial indication dose sensitivity of 5 ppb●hr, meaning at a concentration of 5 ppb of TDI, this badge will indicate exposure after being in the environment for one hour.

– HOW WE DO IT –

SOLUTIONS

Water Treatment Chemicals

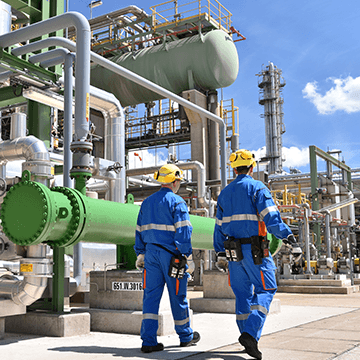

Storage and transfer of bulk chemical for water treatment purposes poses one of the largest opportunities for exposure to water treatment personnel. Calcium hypochlorite available in powder or tablet form, usually contains about 65% chlorine by weight. Because of its water solubility, it is important to store in a cool dry place to prevent unintended release of chlorine gas. Chlorine gas is liquified at room temperature, therefore it is most commonly contained in pressurized cylinders. Generally, the liquified chlorine gas is released from the tanks and injected directly into the water stream for treatment. Chloramines, the combination of chlorine and ammonia compounds, is often chosen over chlorine-only treatment because it produces fewer by-products and has longer lasting effect. Ozone is the strongest of the common disinfecting agents and is extremely unstable in nature, therefore, it must be generated on site. Ozone is manufactured by passing oxygen over two electrodes with high alternating potential difference. Ozone is used to control both taste and color of drinking water. Operators working with water treatment chemicals help ensure their safety by using SafeAir and ChromAir badges to monitor for chemical exposure.

Municipal Water Treatment Plant

Municipal water treatment plants are not only responsible for sanitizing and purifying the drinking water used every day, but also for treating and removing toxins from wastewater for proper disposal. When treating industrial wastewater, operators must be aware of the compounds in the wastewater as well as compounds in the treatment chemicals. They must be cautious not to mix compounds that could react to create additional hazards. Operators have the highest likelihood of exposure when transferring bulk storage chemicals, setting up and maintaining chemical feed systems, and when taking and testing samples for laboratory analysis. SafeAir and ChromAir badges require minimal training. These personal air sampling devices accurately and immediately indicate the presence of toxic chemicals, keeping employees safe from chemical exposure when working in water treatment plants.

Ballast Water Treatment

Ballast water treatment has become an increased focus for large sea faring vessels according to the International Maritime Organization (IMO). While ballast water is essential for safe and efficient shipping operations, the ecological, economic, and health problems raised by the transportation of invasive aquatic species (IAS) in ballast water from one corner of the world to another must be managed. The living organisms transported in ocean faring vessels ballast tanks include bacteria, microbes, small invertebrates, eggs, as well as cysts and larvae of various species. With the increased trade volume over the last several decades, the problem of invasive species settling outside of their native regions is at an all time high. Studies have shown the effects of these bio-invasions are devastating to the native ecosystem. The IMO established the International Convention for the Control and Management of Ships’ Ballast Water and Sediments (BWM Convention) to combat the threat posed by invasive species found in ship’s ballast water. This convention requires all ships to implement a ballast water management plan using approved ballast water management systems. The goal of the regulations is to significantly reduce the number of organisms in ballast water. Active ballast water management systems typically use chlorine or ozone to treat the ballast water. While using ozone and chlorine pose a workplace hazard in normal conditions, there is increased danger of chemical exposure in an enclosed space like the ballast water treatment room of a ship. SafeAir and ChromAir badges can help protect crew members from chemical exposure when working with ballast water treatment systems.

– EXPERIENCE YOU CAN TRUST

MORE INDUSTRIES SERVED

– GET IN TOUCH –