Heavy Manufacturing

– Chemical Detection in the Manufacturing Industry

Manufacturing Common Sense Chemical Safety Procedures

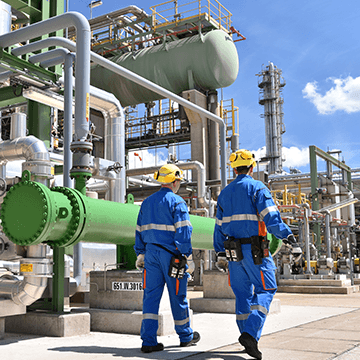

Modern manufacturing sources raw materials and production equipment from around the world. In these manufacturing processes, employees may run the risk of exposure to hazardous materials. Plant managers and safety officers alike know that smart safety practices lead to efficient manufacturing processes and higher production output. Proper training and equipment result in accident prevention. Employees can be trained to use SafeAir and ChromAir badges in a matter of minutes. If the badge shows no color change, you’re in the clear. If you see a color change on your badge, you know you’ve been exposed. Implement SafeAir and ChromAir badges in your chemical safety plan today and ensure the safety of employees working with toxic chemicals.

– Designed for the Manufacturing Industry

Chemicals Detected

– HEAVY MANUFACTURING –

NEWS & UPDATES

The Big Deal – Chemical Detection

What is Chemical detection and why do we need it? Believe it or not, the need for chemical detection is not just prevalent in chemical labs and big science corporations. In fact, the need spreads out over almost every industry in one way or another. From sanitizing...

If I have an area monitor, do I need to do personal monitoring?

Great question! First, let’s quickly talk about what is the difference between an area monitor and a personal monitor. An area monitor, like the name describes, is an instrument placed in a specific area to monitor the chemical concentration in that...

Exposure dose for dummies

To answer the question of how fast SafeAir badges will react, we will need to know the concentration of the chemical present in the environment as well as the overall time of the exposure. For example, the SafeAir TDI/MDI badge has an initial indication dose sensitivity of 5 ppb●hr, meaning at a concentration of 5 ppb of TDI, this badge will indicate exposure after being in the environment for one hour.

– HOW WE DO IT –

SOLUTIONS

Plastic & Rubber Manufacturing

Resins, fillers, pigments, plasticizers, and stabilizers, among other additives, all go into making different variations of finished plastic products. While the finished product is safe for the consumer, each of these ingredients presents a unique chemical hazard to the employees when formulating or processing these polymers. The fumes let off by these unique blends can result in serious health effects for the workers in close proximity. The process of rubber making also presents a unique chemical hazard to employees. This multi-step process uses numerous chemicals and solvents. Until the rubber is fully cured, there remains the potential for employees to be exposed to the toxic fumes let off by the volatile compounds. SafeAir and ChromAir badges can help to keep employees safe when working around toxic chemical hazards like those in plastic and rubber manufacturing.

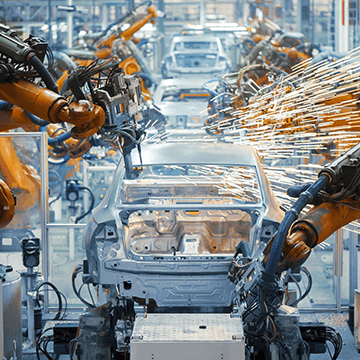

Combustion Engines

Manufacturing processes often rely on heavy equipment or machinery that run on combustion engines. Carbon Monoxide (CO), known as the silent killer, is present in the exhaust from internal combustion engines, such as forklifts, generators, trucks and automobiles. Anyone working in close proximity to such equipment has the potential for carbon monoxide exposure. SafeAir and ChromAir CO badges help ensure employees are safe when working around toxic vapors such as carbon monoxide.

Paper production

Manufacturing paper requires a multitude of bleaching, filling, and coating compounds. These materials include ammonia, chlorine, chlorine dioxide, hydrogen peroxide, hypochlorous acid, magnesium bisulfite, ozone, and various sodium compounds. Pulping can be done through several processes using different chemicals to dissolve lignin to extract cellulose from wood fibers. This wood pulp is then bleached using a chlorine, chlorine dioxide, or hydrogen peroxide-based solution to remove color from the trace amounts of lignin still in the pulp. The many processes involved in the production of paper use a wide array of solvents and chemicals. ChromAir and SafeAir badges help to keep employees safe when working with hazardous materials like those found in the paper production process.

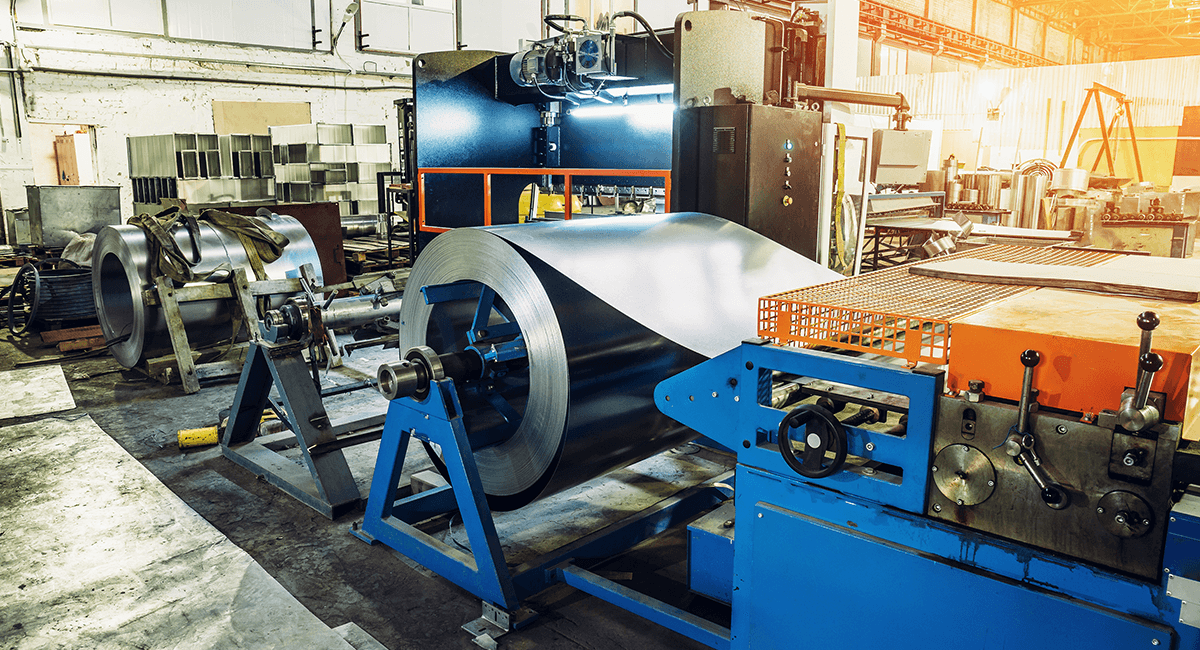

Foundries

The iron and steel industries are diverse in both raw materials, and the processes used to refine them. This diversity exposes foundry workers to a wide variety of substances. Cupola melting and casting operations release carbon monoxide (CO) into the atmosphere. In addition, oil burners, furnaces for annealing and carburizing, and transport equipment used in the foundry all pose the potential for an employee to be exposed to CO. Organic binders can be used when forming cores and moulds, these include furan, phenol-formaldehyde, urea-formaldehyde, and urethane resins. When organic binders are subjected to high temperatures, thermal decomposition can give rise to the formation of additional compounds. While the numerous physical hazards foundry workers face may be straightforward, without the right equipment, identifying a chemical hazard is not. SafeAir and ChromAir badges help to ensure foundry workers are safe from chemical exposure when working in such hazardous conditions.

– EXPERIENCE YOU CAN TRUST

MORE INDUSTRIES SERVED

– GET IN TOUCH –