Here’s How to Know If Exposure Is Happening

In workplaces where polyurethane foams, coatings, adhesives, and elastomers are produced or used, two chemicals pose a real, documented respiratory risk: toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These chemicals are among the primary building blocks of the products industries and consumers rely on every day, from insulation in homes and refrigerators to cushioning in furniture and automotive seating.

Where TDI/MDI Exposure Actually Happens

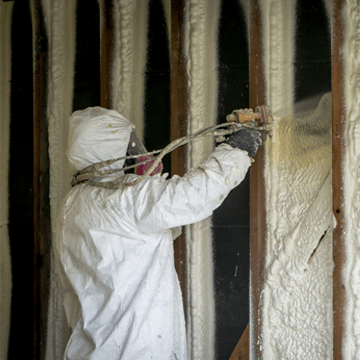

Workers are most at risk when handling these chemicals during spray application, mixing, transfer operations, maintenance, and curing. This is precisely when airborne isocyanates can be present in the breathing zone, even at low levels.

While fully cured polyurethane products do not contain unreacted diisocyanates, exposure during manufacturing and handling can be dangerous even at levels that don’t produce noticeable odor or irritation. Today, we’ll walk through where exposure happens and how you can detect it proactively.

More about Diisocyanates: Fast Facts and Frequently Asked Questions – American Chemistry Council

Why Smell and Symptoms Are Unreliable Indicators

Unlike many workplace hazards, diisocyanates do not always have a strong odor at dangerous concentrations. That means:

- Workers may not smell them even when concentrations exceed safety guidelines.

- Olfactory fatigue can mask odors over time.

- Low-level exposures may not cause immediate irritation.

This disconnect between exposure and perception is why relying on smell, complaint reports, or intuition can lead to false assurances and delayed identification of real exposure issues.

Industry Guidance Shows Exposure Limits Are Low

Occupational exposure limits for diisocyanates are carefully set because even low levels of inhalation can lead to sensitization and adverse respiratory effects.

In the U.S., regulatory bodies like OSHA and professional organizations such as ACGIH have established exposure limits in the parts-per-billion (ppb) range for airborne TDI and MDI. The EU’s REACH restriction on diisocyanates mandates industry responsibility for safe use, including required worker training, risk management, documentation, and ongoing compliance reporting to ECHA.

These limits exist because:

- TDI and MDI are recognized sensitizers, meaning repeated inhalation can lead to asthma and long-term lung issues.

- Sensitization can occur at concentrations below levels noticeable by smell.

- Workplace exposure must be managed with vigilance.

Real Triggers That Reveal Hidden Exposure

Facilities often become aware of exposure issues only after:

- Respiratory symptom complaints

- May include: symptoms of asthma (shortness of breath, cough, chest tightness, and/or wheezing)

- If exposed to high concentrations, diisocyanates may also cause hypersensitivity pneumonitis, with cough, shortness of breath, and fever.

- Regulatory inspections

- Insurance or risk engineering audits

- Incident investigations

- Contractor health reports

Waiting for these triggers can mean exposure has already occurred. Passive screening lets safety managers take a proactive approach.

Spray Foam Safety Training: Spray Polyurethane Foam Chemical Health and Safety Training

Passive Exposure Screening: What It Is and What It Does

Morphix Technologies’ SafeAir TDI/MDI detection badge is a chemical indicator badge designed for passive, visual screening of aromatic isocyanate exposure without the need for electronics, calibration, or complex instruments.

How it works:

- Chemical reagents in the badge react with airborne TDI/MDI.

- The badge changes color when exposure occurs, providing a visual indication.

- A more intense color change correlates with higher cumulative exposure.

- Optional accessories like color comparators help estimate exposure dose.

These badges can be used for area monitoring as well as employee monitoring.

How to Use TDI/MDI Badges Effectively

Here’s a simple 6-step strategy to integrate badge screening into your safety program:

- Identify high-risk tasks where TDI/MDI handling is routine.

- Assign badges to workers to wear near their breathing zone.

- Advise using a buddy system, so they can watch each other’s badges for color changes.

- Evaluate badges after shifts for color change.

- If you see a reddish-pink color in the exclamation mark, TDI or MDI is present in the environment

- Pair the badge with a color comparator.

- The comparator is used to determine TDI (or MDI) exposure dose by matching the color on the badge to a color on the comparator color wheel. It measures TDI(or MDI) exposure dose from 5 to 140 ppb-hour.

- Use results to refine ventilation, work sequences, PPE, and controls.

- Document findings for safety records and internal review.

Because badge screening is easy to implement and requires minimal training, it can be a powerful addition to any industrial safety strategy.

Don’t Wait Until It’s Too Late

TDI and MDI play a critical role in polyurethane chemistry and industrial production, but their benefits come with responsibility. Because these chemicals can produce airborne exposure without obvious odor, relying on sensory judgment is unsafe.

Proactive screening with passive TDI/MDI badges provides the simplest way to know whether exposure is happening.