Welcome back, fellow industry enthusiasts! In the spirit of our upcoming trip to San Antonio for the American Chemistry Council’s Polyurethane Technical Conference, we’re delving into the fascinating world of polyurethane, a versatile material that has made its mark in a plethora of sectors. We’ll explore its applications, the not-so-friendly but oh-so-necessary chemicals involved, and crucial safety measures to keep in mind. So, whether you’re a seasoned pro or a newcomer, join us as we journey through the world of the polyurethane industry.

Polyurethane in the Industry: A Brief Overview

Polyurethane, often referred to as PU, is a remarkable material with wide-ranging applications in construction, automotive, furniture, and more. Its versatility comes from its ability to take on various forms, from soft and flexible foam to rigid and durable coatings.

One of the key factors driving the popularity of polyurethane in the industry is its exceptional durability and resilience. It can withstand extreme temperatures, making it ideal for insulating materials in buildings and ensuring your car’s seats remain comfy no matter the weather.

However, as we dive deeper into the world of polyurethane, we can’t ignore some of the potential hazards associated with its production. Two chemicals, in particular, deserve our attention: Toluene Diisocyanate (TDI) and Methylene Diphenyl Diisocyanate (MDI). Both are vital to the industry, but they differ in terms of reactivity, chemical structure, and physical properties of the resulting polyurethanes. Basically, when they are being used in the production of polyurethanes, the choice is based on the end-goal.

Toluene Diisocyanate (TDI)

TDI is a key ingredient in the production of flexible polyurethane foam, widely used in mattresses, cushions, and car seats. TDI is known for its higher reactivity compared to MDI. It reacts more quickly with polyols, which are the other main component in polyurethane production. This rapid reaction can be advantageous in certain applications where a fast-curing time is required. While its applications are invaluable, TDI comes with potential health risks when not handled properly.

Methylene Diphenyl Diisocyanate (MDI)

MDI is used in many different polyurethane products including spray foam applications and coatings. MDI is less reactive than TDI, which can be an advantage in situations where a longer processing time is needed. The slower reactivity allows for more precise control over the foaming or curing process. MDI also comes with its own set of health regulations and risks if not properly handled.

Safety First: Detecting and Preventing Hazards

Now that we’ve highlighted some potential dangers, let’s shift our focus to safety measures within the polyurethane industry. Also see the CDC’s page on TDI and MDI and their potential health risks here.

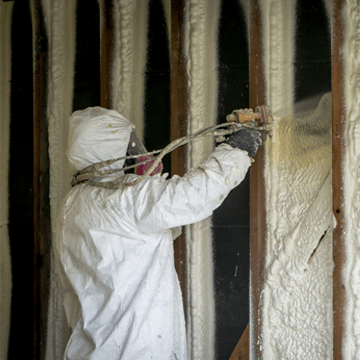

1. Personal Monitoring: Personal protective equipment (PPE) is a must when working with TDI and MDI. I’m sure we’re all familiar with the usual: respirators with the appropriate cartridges, gloves, goggles, and coveralls that help mitigate risks. Lesser though about additions to PPE such as chemical detection badges or monitors help to determine an individual’s exposure to the chemical. Badges like the SafeAir badge not only alert a wearer to prevent exposure in life-threatening amounts but can give an accurate measurement of and individual’s total exposure. It’s this kind of monitoring that keeps workers healthy and ensures they are not exceeding regulations. Regular health check-ups are also essential to monitor any potential exposure.

2. Leak Detection: Installing leak detection systems is crucial for large-scale polyurethane manufacturing facilities. These systems can swiftly identify any leaks or spills, triggering immediate responses to contain and neutralize the hazard.

3. Workplace Air Monitoring: Continuous air quality monitoring in the workplace is vital. Specialized instruments can detect the presence of harmful gases and trigger alarms if thresholds are exceeded. This ensures quick evacuation and response, protecting workers from exposure.

4. Employee Training: Well-informed and trained employees are your first line of defense against potential hazards. Regular training on safe handling practices, emergency response, and the proper use of PPE is essential.

Did you know that the Morphix SafeAir Chemical Detection badge is ideal for employee monitoring and leak detection? Take a look at the badge and its color comparators available here.

Raising Awareness: The Path to a Safer Industry

While we’ve discussed some crucial safety measures, it’s equally important to consider the broader context. Raising awareness about the potential hazards of working with TDI and MDI is vital for industry-wide improvement.

Polyurethane in the industry is undeniably indispensable, thanks to its versatility and durability. However, we must remain vigilant when working with chemicals like TDI and MDI. By prioritizing safety measures such as personal monitoring, leak detection, and employee training, we can mitigate risks and ensure a secure work environment.

Ultimately, it’s not just about industry professionals; it’s about creating a safer and more sustainable future for everyone. So, let’s continue to innovate and raise awareness within the polyurethane industry, building a brighter and safer tomorrow.

Remember, in the world of polyurethane, safety always comes first.