Petrochemical

– Chemical Detection in the Petrochemical Industry

Drilling down common-sense chemical safety practices

Due to the many hazards found in the oil and natural gas industry, a strong safety focus is necessary. From mercury containing crude-oil to chemical hazards released by the refining process, workers face many sources of potential chemical exposure in the petrochemical industry. Proper employee training of chemical safety procedures, facility-wide risk analysis, early warning systems, and preparedness for treating chemical exposure are integral aspects of an effective chemical safety plan. SafeAir and ChromAir badges are personal air sampling monitors ideal for screening employee exposure to toxic chemicals. These chemical detection badges help to ensure employees in the petrochemical industry are safe by indicating exposure to hazardous chemicals at levels well below a dangerous dose.

– Designed for the Petrochemical Industry

Chemicals Detected

– PETROCHEMICAL –

NEWS & UPDATES

The Big Deal – Chemical Detection

What is Chemical detection and why do we need it? Believe it or not, the need for chemical detection is not just prevalent in chemical labs and big science corporations. In fact, the need spreads out over almost every industry in one way or another. From sanitizing...

If I have an area monitor, do I need to do personal monitoring?

Great question! First, let’s quickly talk about what is the difference between an area monitor and a personal monitor. An area monitor, like the name describes, is an instrument placed in a specific area to monitor the chemical concentration in that...

Exposure dose for dummies

To answer the question of how fast SafeAir badges will react, we will need to know the concentration of the chemical present in the environment as well as the overall time of the exposure. For example, the SafeAir TDI/MDI badge has an initial indication dose sensitivity of 5 ppb●hr, meaning at a concentration of 5 ppb of TDI, this badge will indicate exposure after being in the environment for one hour.

– HOW WE DO IT –

SOLUTIONS

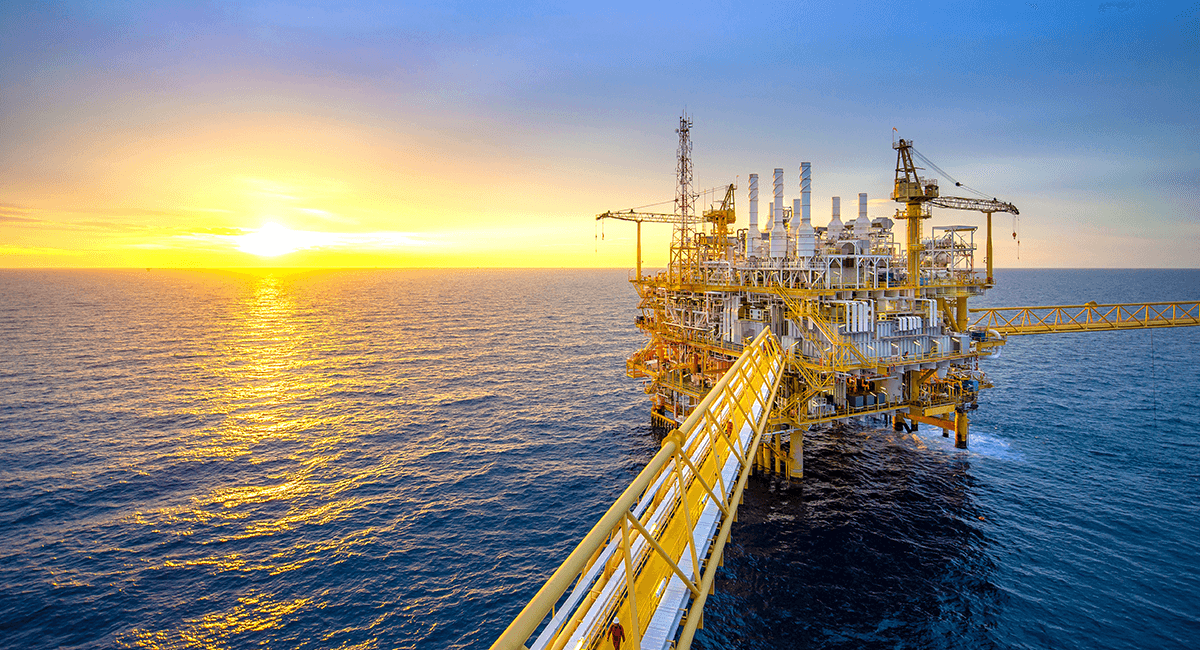

Oil Drilling

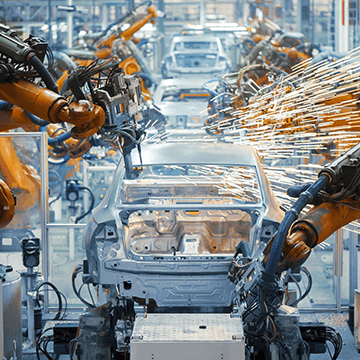

Many industrial processes work in conjunction with one another to successfully drill and extract oil and gas. These processes each pose a unique hazard to workers on oil derricks and drilling rigs. In addition to the obvious occupational hazards of working around heavy machinery and moving parts, workers extracting oil and gas can also face the more invisible threat of chemical exposure. Examples of chemical threats include high mercury content in petroleum in some part of the world, and the multitude of chemicals in the pressurized liquid used for fracking. Chemicals used in the oil and natural gas extraction processes pose an increased danger to employees working in an enclosed space. SafeAir and ChromAir badges help workers in the petrochemical industry stay safe by identifying toxic chemicals before the employee receives a dangerous dose.

Flue Gas Emissions

Flue gas emissions in the petroleum refinery process results from the combustion of gas and oil in gas turbines, boilers, engines, and process heaters. These processes emit a number of chemicals including carbon dioxide (CO2), nitrogen oxides (NOx), sulfur oxides (SOx), carbon monoxide (CO), and small amounts of hydrogen sulfide (H2S). SafeAir and ChromAir badges allow employees to monitor for toxic flue gas emissions, thus helping to keep employees working in the oil and natural gas industry safe from chemical exposure.

Venting and Flaring

Venting and flaring are used in non-routine operations at petroleum refining facilities as a means to safely dispose of vapors. Flaring modifies, by means of combustion, the chemical nature of the substances being emitted, presenting the opportunity for occupational exposure to other hazardous compounds. SafeAir and ChromAir badges allow employees to monitor for toxic gases as a result of venting and flaring.

Fugitive Emissions

Fugitive emissions, emissions not meant to be released, are a source of potential employee exposure in the petroleum industry. Fugitive emissions can occur during the storage, loading and unloading of hydrocarbons, or from leaks from a wide variety of refinery systems, such as tubing, valves, seals and conveyance systems. SafeAir and ChromAir badges allow employees to monitor their exposure to toxic gases released as fugitive emissions.

Wastewater

A large amount of industrial wastewater is created each year as a biproduct of the petroleum fracking and refining processes. Wastewater from refining is generated by several processes including desalting, topping, vacuum distillation, pretreating, distillate hydrodesulfurization, cracking, and coking. This wastewater can be contaminated with a variety of chemicals such as hydrocarbons, hydrogen sulfide, and ammonia. Petroleum wastewater is treated through physical, biological, and chemical means. Both the chemicals in wastewater and the chemicals used to treat it can pose health hazards to employees. SafeAir and ChromAir badges allow employees to monitor for exposure to toxic gases released from wastewater and its treatment.

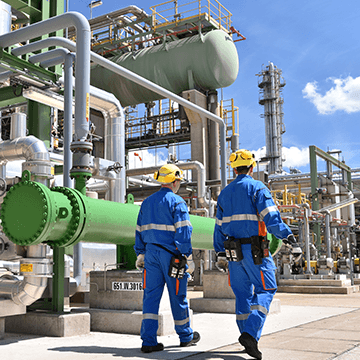

Refining

Petroleum refining facilities manufacture, use, and store significant amounts of hazardous materials that can pose a danger to employees. For instance, hydrogen sulfide leaks may occur from amine treatment units, and carbon monoxide leaks may occur from cracking units. Occupational health and safety professionals work to mitigate the hazards and provide a safe working environment for employees in the petroleum refining industry. SafeAir and ChromAir badges help to keep employees working around toxic hazards in the oil and natural gas industry safe from chemical exposure.

– EXPERIENCE YOU CAN TRUST

MORE INDUSTRIES SERVED

– GET IN TOUCH –