Breaking down formaldehyde hazard detection. We’ve all been there, it’s that time again for calibration and re-training for the company’s chemical detection equipment. A few hours, or a couple of training sessions broken up over several days makes this one of the least looked-forward-to times of year. Not to mention, most people in these trainings won’t remember how to use this equipment, so as the EHS manager, you’ll still get bombarded with daily questions and emails. You ask yourself, “Why does safety have to be this complicated?!”.

Formaldehyde is a common industrial chemical used in various manufacturing processes and it comes with some high risks. Safety and effective hazard detection is key to ensure workplace safety.

Understanding Formaldehyde Hazards – Regulatory Standards

Formaldehyde has set exposure limits in the USA including the below from regulatory institutions.

OSHA PEL (Permissible Exposure Limit) of 0.75ppm (parts per million). This calculation uses an 8-hour time-weighted average.

NIOSH REL (recommended exposure limit) of 0.016ppm (parts per million). This is calculated from an 8-hour time weighted average. NIOSH also advises handling formaldehyde as a potential occupational carcinogen in the workplace.

Understanding Formaldehyde Hazard Detection – Traditional methods of detection

Traditional methods for detecting formaldehyde in industrial settings include electronic sensors, sorbent tubes, and spectrophotometry. Electronic sensors, such as electrochemical and metal oxide sensors, offer continuous monitoring but require calibration, maintenance, and can be costly. Sorbent tubes, often used for air sampling, involve drawing air through a chemical-coated tube and sending it to a lab for analysis—providing accurate results but lacking real-time detection. Spectrophotometry, including UV-Vis and fluorescence-based methods, delivers high sensitivity and specificity but requires expensive equipment and trained personnel. These methods, while effective, can be impractical for frontline workers who need simple, immediate hazard identification.

Simplifying Formaldehyde Detection – Chemical Detection Badges

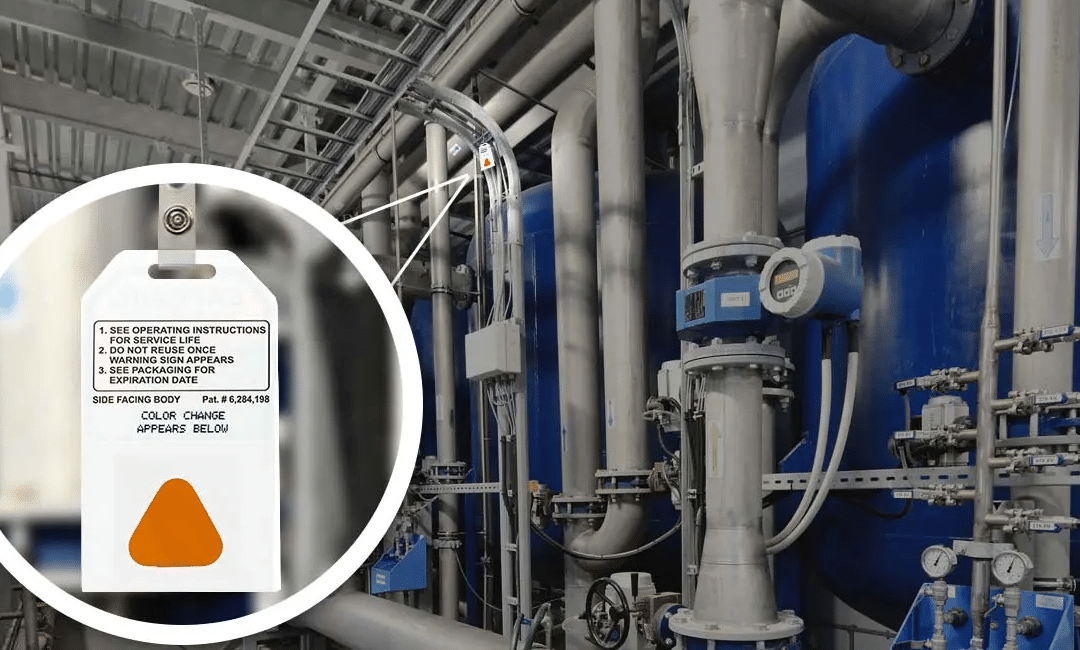

Colorimetric chemical detection badges change the game when it comes to workplace safety. In an environment where the end-user’s safety is paramount, it just makes sense to put practical, useable detection capabilities in their hands. Chemical detection badges don’t require specialized training and produce an immediate visual indication. Morphix SafeAir and ChromAir Formaldehyde badges provide a direct-read visual indication of formaldehyde detection. Place badges in the wearer’s breathable zone for personal monitoring or hang them as area monitors.

ChromAir and SafeAir Formaldehyde Badges – Choosing the right detection solution

SafeAir formaldehyde badges provide an immediate color changing indication in the form of a universal warning sign (exclamation mark) in the viewing window. The color change is indicated by a change from yellowish-brown to dark brown. These badges detect formaldehyde at a threshold level of 0.2 ppm∙hr with a minimum detectable limit of 0.025ppm (8 hours).

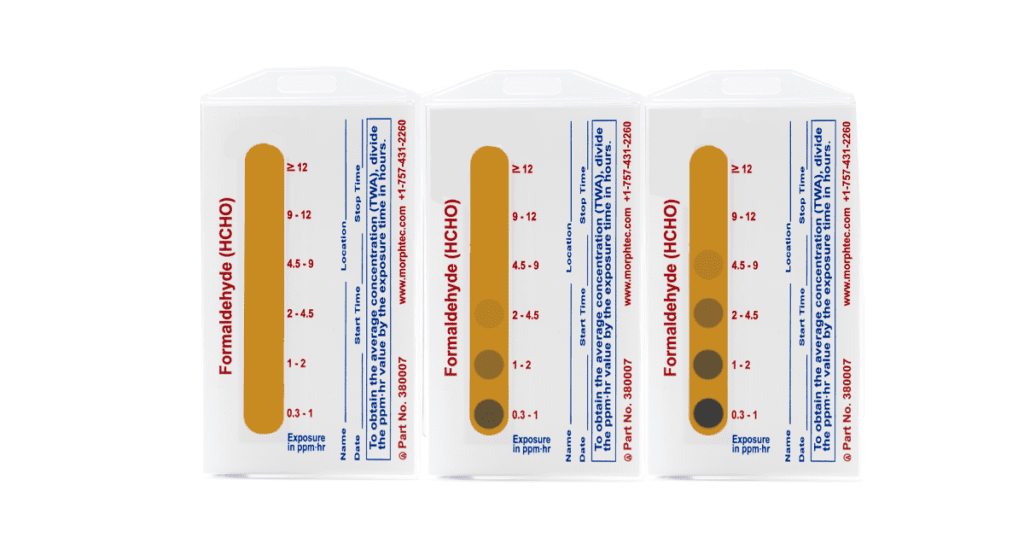

ChromAir formaldehyde badges provide an immediate indication through a series of color-changing cells. The ChromAir passive monitor is a patented direct-read autogenic exposimeter. The device consists of six cells, with one side attached to a flat indicator layer and the other to a series of different diffusive resistances. Formaldehyde gas diffuses to the cells through the different diffusive resistances and reacts with the indicator layer, producing color change from yellowish-brown to brown. The color produced is a direct measure of the exposure dose. Visual color is achieved by observing the formation of the brown threshold color on the individual cell and reading the corresponding exposure dose. These badges detect formaldehyde from 0.3 – 12 ppm•hr.

Analyzing Traditional Detection Methods

Traditional formaldehyde detection methods—like electronic sensors, sorbent tubes, and spectrophotometry—can be a hassle. Sensors need regular calibration and maintenance, which gets expensive fast. Sorbent tubes require lab testing, meaning you won’t get results right away, delaying critical exposure awareness and limiting real-time decision-making. Spectrophotometry, while highly sensitive, is costly and requires trained professionals to operate.

Even electronic gas monitors also have their drawbacks. They are great for continuous formaldehyde detection, but these monitors need regular calibration and maintenance, which adds up in both time and cost. Many models require trained personnel to operate and interpret the readings, making them less practical for everyday use by end users. Battery life and sensor lifespan can also be limiting factors, especially in high-use environments.

That’s where ChromAir and SafeAir formaldehyde badges come in. They’re affordable, low-maintenance, and give you an instant read on exposure. With their easy-to-read color change, there’s no guesswork—just clear, reliable formaldehyde hazard detection that anyone can use on the spot.

Want additional information on the SafeAir and ChromAir Chemical Detection Badges? Check out their product page for operating instructions, trainings, and more information to help your workplace inch towards an even safer environment.