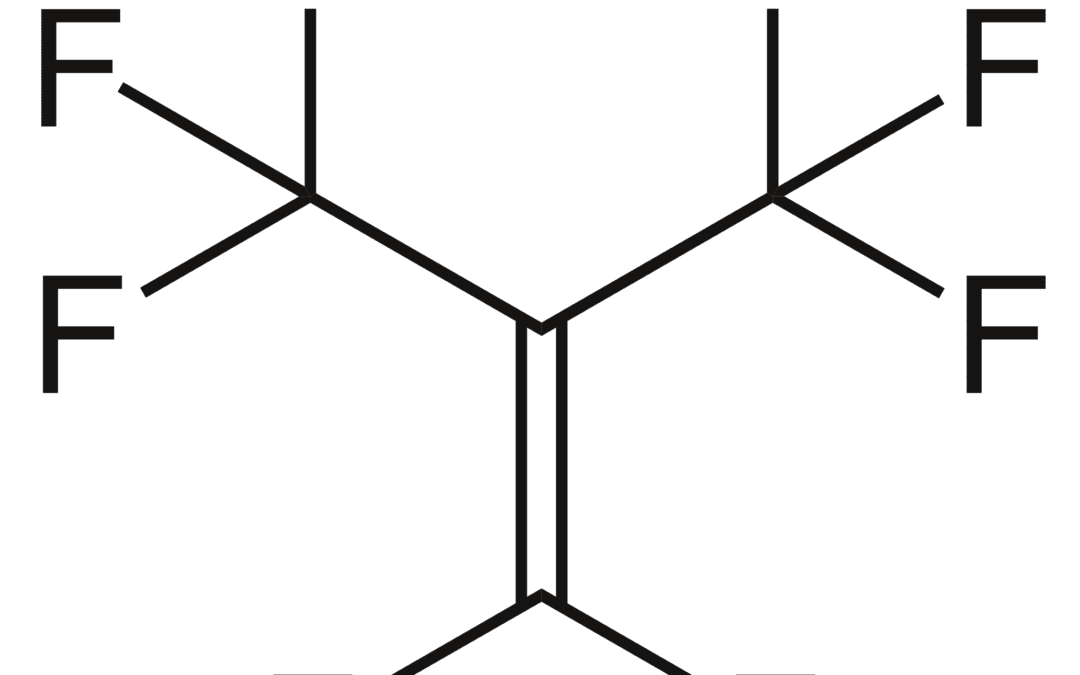

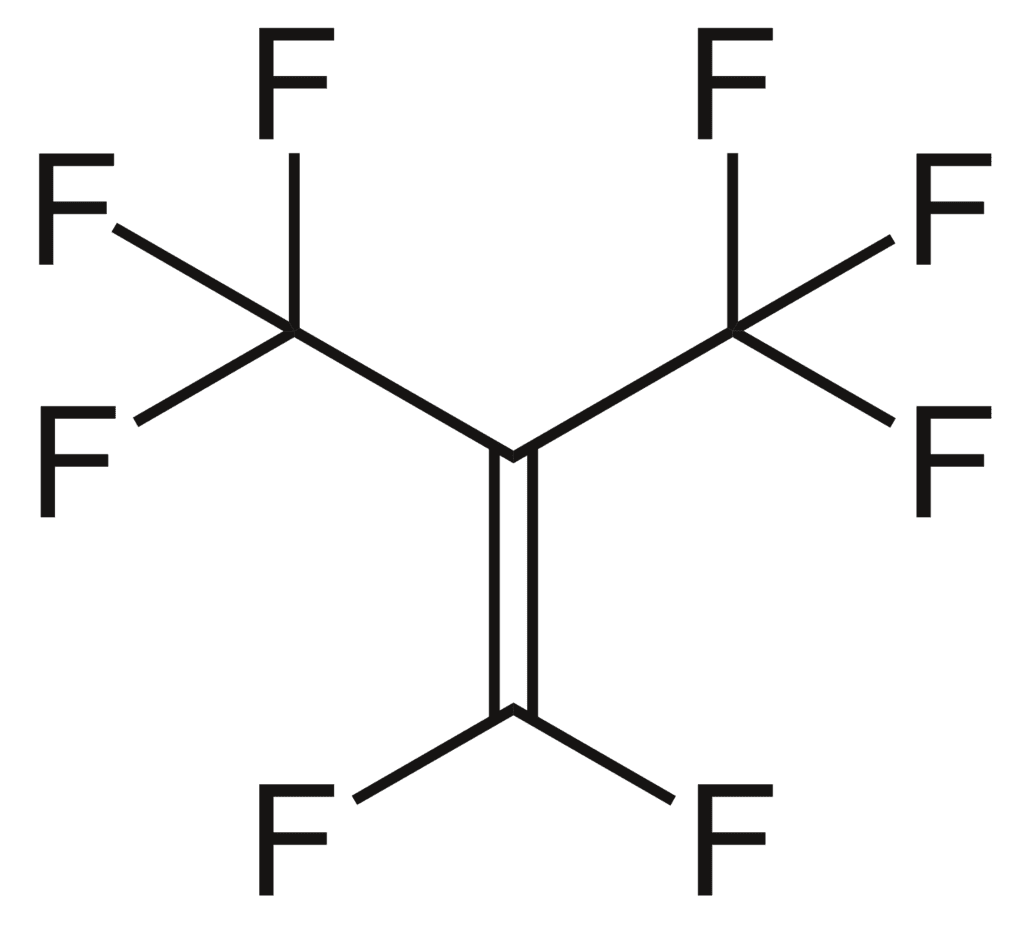

What is Perfluoroisobutylene?

Perfluoroisobutylene, also known as PFIB, is a very dangerous and toxic chemical. It is a byproduct in the production of very important and useful chemicals. In the manufacturing process, PFIB is captured and the elimination is highly controlled to ensure that employees are safe. Even though this process has been around for decades, there has not been an effective tool to monitor employee exposure. Yes, there are instruments capable of detecting PFIB, but not a cost-effective solution for every employee.

The fluoropolymer industry has a strong reputation for employee safety. Over the years, efforts have been made to develop technologies to detect PFIB for employee monitoring but with little success. One of the leading manufacturers, partnered with Morphix to develop a dosimeter badge for PFIB. Through this collaboration, a SafeAir badge for PFIB was developed and validated. The SafeAir PFIB badge detects PFIB at 3 ppm.min under a wide range of environmental conditions. This new badge will provide protection to thousands of workers around the world who may potentially be exposed to PFIB.

More about PFIB

Perfluoroisobutylene, or PFIB, is a colorless gas at room temperature and has a high density, making it heavier than air.

The versatility of PFIB has led to its incorporation in various industrial processes. A primary application is in the production of specialty fluoropolymers, known for their exceptional properties such as chemical resistance and electrical insulation. PFIB’s role as a precursor in the creation of these polymers underscores its importance in the manufacturing sector. However, this significance also raises the stakes in terms of safety considerations.

PFIB has woven itself into the fabric of several industries, including electronics, aerospace, and chemical manufacturing. Its presence is particularly felt in the production of advanced fluoropolymer-based products, from non-stick coatings to intricate components in electronic devices.

To ensure the safe handling of PFIB, it is imperative for industries and workers to implement robust safety measures. This includes the use of appropriate personal protective equipment (PPE), such as respirators and chemical-resistant gloves, as well as the installation of adequate ventilation systems in workspaces where PFIB is used. Regular training sessions on proper handling procedures and emergency response protocols are also crucial components of a comprehensive safety strategy.