More Than Just a Household Cleaner

Ammonia is far more versatile than simply the household cleaner you might associate with its distinctive smell. This critical chemical is used in countless industries, and its unique properties make it indispensable for many applications. Before diving into workplace ammonia safety and monitoring solutions, let’s explore what ammonia is and why it plays such a vital role in industrial processes.

What Is Ammonia?

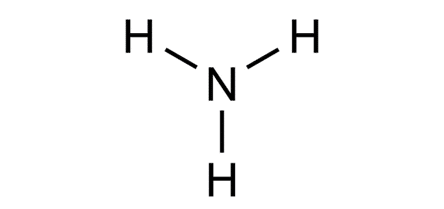

Ammonia, with the molecular formula NH₃, is a compound composed of nitrogen and hydrogen. Its reactivity stems from its basic properties, ability to form hydrogen bonds, and ligand characteristics. These attributes make ammonia a staple in a wide range of industrial applications.

Ammonia Safety – What are the exposure limits

To safeguard workers, regulatory agencies have set clear limits for ammonia exposure:

OSHA’s Permissible Exposure Limit (PEL):** 50 ppm (8-hour time-weighted average)

NIOSH’s Recommended Exposure Limit (REL):** 25 ppm (8-hour time-weighted average)

OSHA also recommends several on-site screening methods for monitoring ammonia, including colorimetric detection.

Where Can You Find Ammonia?

Ammonia serves a wide range of industries. Here are some of the most common sectors that rely on it:

1. Fertilizer Production: Ammonia provides an essential source of nitrogen, a critical nutrient for plants. For over 100 years, agriculture has relied on ammonia to produce fertilizers, with approximately 85% of global ammonia supporting food production.1

2. Industrial Refrigeration: Ammonia is a cost-effective refrigerant, valued for its efficiency at high temperatures.

3. Chemical Manufacturing: Its stabilizing reactions and basic nature make ammonia integral to the production of various chemicals including nitric acid, amines and isocyanates.

Health Risks of Ammonia Exposure

Exposure to ammonia, especially at high or repeated concentrations beyond recommended limits, can lead to serious health issues, including:

– Irritation: Eyes, nose, throat.

– Respiratory Problems: Difficulty breathing (dyspnea), wheezing, chest pain, and pulmonary edema.

– Skin Damage: Burns, blisters, or frostbite from liquid ammonia.

– Severe Cases: Pink frothy sputum indicating fluid in the lungs.

Workplace exposure can occur through accidental leaks, equipment malfunctions, or transportation spills, among other incidents.

How to Minimize Exposure Risks

While risks can never be eliminated entirely, they can be managed effectively. Best practices for storage and handling include adhering to strict PPE guidelines and ensuring proper employee training.

Ammonia Detectors (like the SafeAir and ChromAir Ammonia Badges) provide reliable, real-time monitoring to help protect employees. These tools offer an added layer of safety by detecting ammonia exposure promptly, reducing risks and fostering a healthier workplace.

Stay Informed on Ammonia Safety

Real-time ammonia monitoring is essential to maintain a safe and productive workplace. By implementing protective measures and utilizing advanced detection systems, employers can safeguard their teams from potential risks. Follow our ammonia blog series for deeper insights into this versatile chemical, its applications, safety solutions, and answers to common industry questions.